Problems associated with cooling systems before treatment:

- Scaling and corrosion of pipes caused by biological activity (biofilm and algae growth)

- Fouling of filling material caused by algae in cooling tower

- Frequent emptying of basins from sludge and bioactive material

- Poor heat transfer due to biofilm formation – loss of energy / money

- Usage of dangerous chemicals in case of algae growth prevention

- Generally high operating and maintenance costs

- No effective on-line biological activity control

Positive effects after anolyte treatment of cooling system

- Elimination of biofilm and algae formation

- Increased heat transfer – lower energy loss

- Increased working time of cooling system

- Usage of ecologically friendly substances (Anolyte)

- Excellent dosing control through Redox potential measurement / control

- Savings on energy

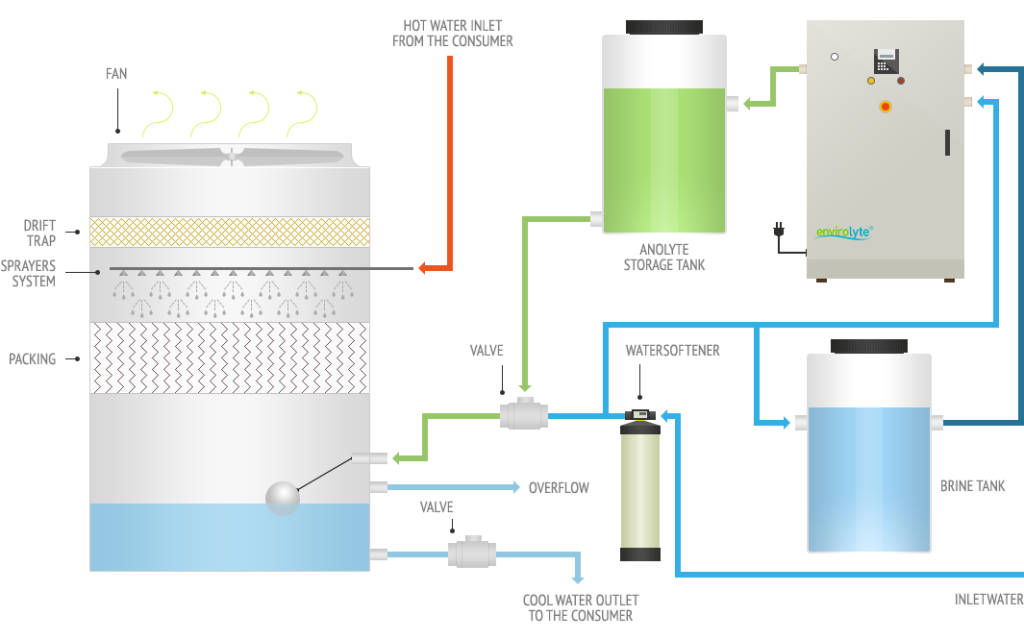

ON SITE INSTALLATION OF ENVIROLYTE UNITS FOR COOLING WATER TREATMENT